- Vacuum Annealing Furnace 1800▲C

- Vacuum Sintering Furnace

- Heat Treatment Furnace

- Drop Bottom Sintering Furnace

- Car Bottom Furnace

- Roller Hearth Furnace

- Mesh Belt Furnace

- Continuous Mesh Belt Furnace

- Ceramic Tiles Roller Furnace

- Roller Kiln

- Industrial Kilns

- Shuttle Kiln

- Tunnel Kilns

- Bogie Hearth Furnaces

- Rotary Kilns

- Pusher Kilns

- Ceramic Roller Kilns

- Sintering Furnace

- Annealing Furnace

- Vacuum Heat Treatment Furnace

- Vacuum Hardening Furnace

- Tempering Furnace

- Continuous Heating Furnace

- Crucible Furnace

- Glass Melting Furnace

- Muffle Furnace

- Gold Melting Furnace

West Of Kelong South Road, Luoxin Industrial Park, Xinan County, Luoyang, Henan, China.

+86-379-60193738

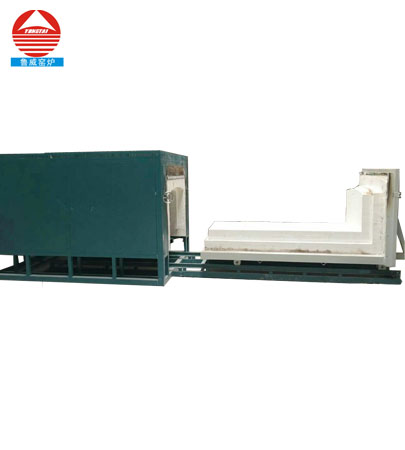

Tempering Furnace

- Brand Name: Luwei

- Model: Tempering Furnace 1200째C

- Max.Temperature: 1200째C

- Working Temperature: 1200째C

- Furnace Chamber Size: 1000*1000*1000MM

- Temperature Controller: PID and SCR

- Control Accuray: 짹 1째C

- Heating Element: SiC heaters

- Thermocouple: S type

- Chamber Material: High purity Ceramic fiber

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air.

Tempering Furnaces are batch type units equipped with recirculating fan(s) and gas-fired or electric heating systems. Tempering Furnaces are designed for tempering or stress relieving in air, nitrogen, argon or hydrogen atmospheres. Tempering Furnaces are used for a variety of heat treating applications including those requiring inert atmospheres.

Tempering Furnaces for both low and high tempering processes. These Tempering Furnaces provide a reliable platform for acquiring various mechanical properties during tempering and reduce the residual stresses during the stress relieving process.

The temperature Category: 1000째C 1200째C 1400째C 1600째C 1700째C 1800째C.

Technical Specifications of Tempering Furnace |

|

Chamber size |

1000x1000x1000mm (Width * Height * Depth) (8 Liter) |

Max. temperature |

1200째C (<2hour) |

Working temperature |

1200째C |

Temperature controlling |

PID automatic control via SCR (Silicon Controlled Rectifier) power control with phase angle fired, current limiting resistor. |

16 programmable segments for precise control of heating rate, cooling rate and dwell time. |

|

Built in PID Auto-Tune function with overheating & broken thermocouple broken protection. |

|

Over temperature protection and alarm allows for operation without attendant. |

|

Temperature accuracy |

짹1째C |

Temperature Uniformity |

짹5째C |

Heating rate |

0-15째C/min |

Thermocouple |

S type with 99.7% purity Alumina tube |

Heating element |

SiC Heating element |

Furnace Chamber |

Three layers of ceramic fiber insulation materials |

Furnace structure |

Double layer steel casing with dual cooling fan, surface temperature below 60째C |

Furnace door |

Front-side open |

Power cutting off when furnace door open |

|

Working voltage |

220V or 380V, 50HZ or 60HZ |

Rated power |

30 KW |

N.W/G.W |

1200KG/1500KG |

Stander chamber size (mm)customize |

2500x500x500 600x600x600 800x800x800 900x900x900 1000*1000*1000 1200*1200*1200 1500*1500*1500 1800*1200*1200 2000*1000*1000 |